RP 400 koronto caadi ah graphite

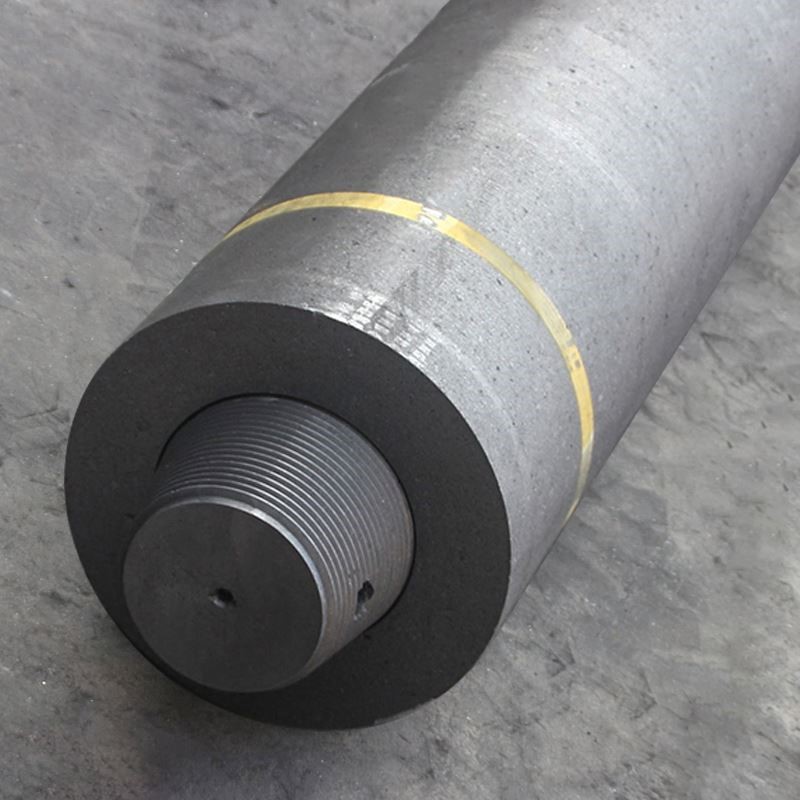

RP 400mm Graphite Electrode

Qalabka leh cabbirka walxaha isku celceliska ah, xoogga iyo qallafsanaanta alaabta leh iska caabbinta hooseeya ayaa sidoo kale wax yar ka hooseeya kuwa leh caabbinta sare.

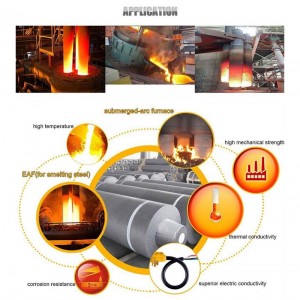

Qalabka leh cabbirka walxaha isku celceliska ah, xoogga iyo qallafsanaanta alaabta leh iska caabbinta hooseeya ayaa sidoo kale wax yar ka hooseeya kuwa leh caabbinta sare. Taasi waa, heerka dheecaanka, khasaaruhu wuu kala duwanaan doonaa. Sidaa darteed, iska caabbinta dabiiciga ah ee qalabka elektiroonigga ah ee graphite, codsiyada la taaban karo waxay u baahan yihiin in la doorto walxaha waa mid aad muhiim u ah. Doorashada walxaha korantada waxay si toos ah ula xiriirtaa saameynta dheecaanka. Ilaa xad weyn, xulashada maaddadu waa ku habboon tahay, taas oo go'aamisa xawaaraha dheecaanka, saxnaanta mashiinka iyo qallafsanaanta dusha sare. Sababtoo ah shuruudaha tayada kala duwan ee awoodda caadiga ah, awoodda sare iyo awoodda ultra-high graphite electrode, isku-darka isku-darka diyaarinta ayaa sidoo kale ka duwan. Marka la eego isbeddellada wax soo saarka warshadaha, horumarinta graphite electrode ilaa korantada awoodda ultra-sare waa isbeddelka mustaqbalka. Kala-goysyada waxaa lagu samayn karaa badhamada 3 ama 4 waxaana lagu soo saaray si adag gudaha heerka dulqaadka warshadaha. Qeexitaannada dheer iyo kuwa gaabanba waxaa loo habeyn karaa iyadoo loo eegayo shuruudaha macaamiisha, waqti gaaban oo wax-soo-saarka, awoodda wax-soo-saarka xooggan, si loo daboolo baahiyaha macaamiisha gudaha iyo dibaddaba.

| Guryaha caadiga ah | |||

| Guryaha | Booska | Unug | RP |

| 300-800mm | |||

| Iska caabin gaar ah | jir | μΩm | 7.8-8.8 |

| ibta naaska | 5.0-6.5 | ||

| Bendin Strengh | jir | mpa | 7.0-12.0 |

| ibta naaska | 15.0-20.0 | ||

| Modulka dhalinyarada | jir | cpa | 7.0-9.3 |

| ibta naaska | 12.0-14.0 | ||

| Cufnaanta Bulk | jir | g/cm³ | 1.60-1.65 |

| ibta naaska | 1.70-1.74 | ||

| CTE (100-600℃) | jir | ×10-6/℃ | 2.2-2.6 |

| ibta naaska | 2.0-2.5 | ||

| Waxyaabaha Dambaska ah | % | 0.5 | |