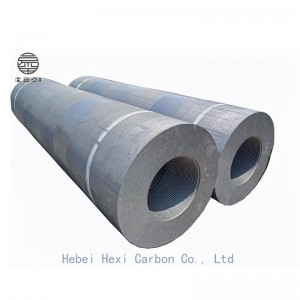

400 UHP graphite electrode

Electrodes-ka graphite waxa inta badan loo isticmaalaa habka birta samaynta. Iskaraabka birta ayaa lagu dhalaalinayaa foornada arc koronto oo dib loo warshadeeyay. Kaari ahaan, waxay yihiin qayb muhiim ah oo ka mid ah noocaan oo kale

UHP graphite electrode inta badan waxay ka kooban tahay coke irbad tayo sare leh, waxaana si weyn loogu isticmaalaa foornooyinka koronto ee aadka u sarreeya. Waxay awood u leedahay inay qaado cufnaanta hadda jirta in ka badan 25A/cm2

| Isbarbardhigga Tilmaamaha Farsamada ee UHP Graphite Electrode 16" | ||

| Electrode | ||

| Shayga | Unug | Specifier Alaabta |

| Astaamaha Caadiga ah ee Cirifka | ||

| Dhexroor Magaca | mm | 400 |

| Dhexroorka ugu badan | mm | 409 |

| Dhexroor Min | mm | 403 |

| Dhererka magacaaban | mm | 1600/1800 |

| Dhererka ugu badan | mm | 1700/1900 |

| Dhererka min | mm | 1500/1700 |

| Cufnaanta Bulk | g/cm3 | 1.68-1.73 |

| xoog leexleexan | MPa | ≥12.0 |

| Dhallinta Modulus | GPA | ≤13.0 |

| Iska caabin gaar ah | µΩm | 4.8-5.8 |

| Cufnaanta ugu badan ee hadda | KA/cm2 | 16-24 |

| Awood Qaadashada Hadda | A | 25000-40000 |

| (CTE) | 10-6℃ | ≤1.2 |

| nuxurka dambaska | % | ≤0.2 |

| Tilmaamaha Caadiga ah ee Ibta Naaska (4TPI) | ||

| Cufnaanta Bulk | g/cm3 | 1.78-1.84 |

| xoog leexleexan | MPa | ≥22.0 |

| Dhallinta Modulus | GPA | ≤18.0 |

| Iska caabin gaar ah | µΩm | 3.4-4.0 |

| (CTE) | 10-6℃ | ≤1.0 |

| nuxurka dambaska | % | ≤0.2 |

Habka wax soo saarka

Electrode graphite inta badan waxa uu ka samaysan yahay coke batroolka iyo coke irbadda, oo lagu qaso garoon dhuxul ah, iyada oo la marayo hababka calcinations, cajiin, samaynta, dubista, garaafaynta iyo machining, ugu dambayntii si ay u noqdaan wax soo saarka. Waa kuwan qaar ka mid ah sharraxaadaha habka wax soo saarka qaarkood:

Kneading: Walaaqda iyo isku darka xaddi gaar ah oo qayb kaarboon ah iyo budo iyo qadar go'an oo xidhaha ah heerkul gaar ah, habkan waxa loo yaqaan cajiin.

Shaqada cajiin

① Isku qas dhammaan noocyada alaabta ceeriin si siman, isla mar ahaantaana u samee walxaha kaarboon adag ee cabbirrada kala duwan si isku mid ah u walaaq oo u buuxi, oo wanaaji cufnaanta isku dar ah;

②Ka dib markaad ku darto asphalt dhuxusha, dhammaan walxaha si adag isugu diyaari.

③Qaar ka mid ah garoommada dhuxusha ayaa gala meelaha bannaan ee gudaha, taas oo sii wanaajisa cufnaanta iyo ku dheggan koollada.

Samaynta: Xabagta kaarboonka ee la cajiimay waxa lagu siidaayaa jidh cagaaran (ama badeeco cagaaran) oo leh qaab gaar ah, cabbir, cufnaan iyo xoog ku jira qalabka qaabaynta. Xabadu waxay leedahay cillad balaastiig ah oo hoos timaada xoogga dibadda.

Dubo sidoo kale loo yaqaan dubista, Waa daawaynta heerkul sare, samaynta garoon dhuxusha carbonized si kookaha la sameeyay, kaas oo xoojiya isku darka carbonaceous iyo qaybaha budada wada jir ah xoog farsamo sare, iska caabin hoose, xasilloonida kulaylka wanaagsan iyo xasiloonida kiimikada.

Dubida labaad waa in la dubto hal mar oo kale, taas oo ka dhigaysa garoonka galka kaarboonays . Electrodes (dhammaan noocyada marka laga reebo RP) iyo ibta naaska u baahan cufnaanta bulk sare ayaa loo baahan yahay in la dubay, iyo ibta naaska saddex-dhuuqo afar-dubi ama laba-dhuujin saddex-dubi.